Our hands and eyes are the most vital equipment when welding in our personal tool bag. Just like wearing the appropriate safety glasses on our faces, we must also wear the appropriate welding gloves since protecting our hands is just as crucial as protecting our eyes. We need to know potential risks before choosing the appropriate welding gloves to know what they should protect us against.

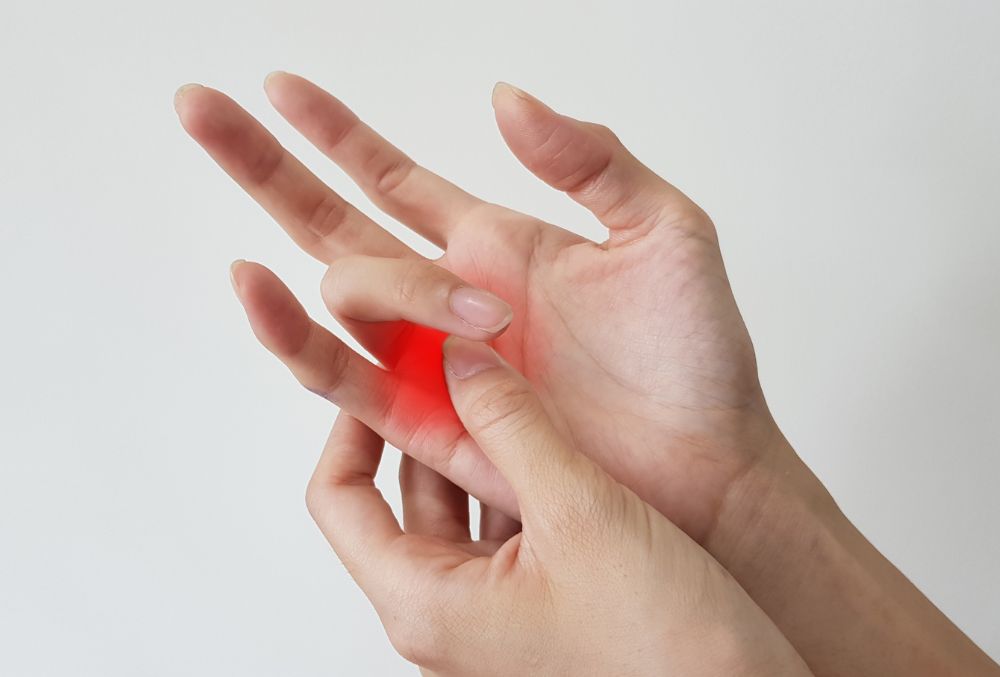

In the field of welding, there are several risks to your hands. If your hands become trapped or pressed between two objects, they may be broken or crushed. By exposing your hands to jagged edges and other surfaces, you risk cutting them. Red-hot metal, sparks, and other hot flying metals can all cause hand burns.

Aside from UV radiation, gloves shield our hands from the brilliant light the welding arc emits. You often encounter additional chemical dangers and cleaning chemicals in the welding industry. Finally, there is a ton of dust, dirt, grease, and grime on and around metal surfaces.

Types Of Welding Gloves

Welders’ hands are shielded from the risks of welding by welding gloves, considered personal protective equipment (PPE). These gloves provide abrasion resistance, improved grip, and digit articulation while shielding the user from electrical shock, extremely high temperatures, and UV and infrared radiation.

According to EN 12477:2001, the design of welding gloves is especially important because of how close they are to the welding process compared to other welding ensemble components, such as the helmet and coveralls. With separate sheaths for the fingers and thumb, gloves are worn over the hand. It should be mentioned that although welding mittens exist, they are typically less useful.

Whatever the case, the fundamental design philosophy remains the same: These garments are made of strong, electrically nonconductive, and heat-dissipating materials. The addition of more materials will improve the protection provided by the glove. Many gloves have oversized cuffs that act as a vambrace-like barrier against forearm spatter.

Choosing the right glove for each application will be aided by knowing what your hands will be exposed to. The kind of gloves we use will vary depending on our welding procedure.

Gloves for TIG Welding

Goatskin or equivalent thin, supple material is the glove of choice for most TIG applications. They give the precision TIG welds formed with a torch exceptional mobility. TIG gloves won’t offer as much protection for hotter operations that produce more spatter because the process produces less.

Additional cushioning is inside the palm or outside of the hand on some of Miller’s TIG gloves. Although they have received positive reviews, Tillman’s simple goatskin gloves are among the best-selling TIG welding gloves due to their superb fit. Using a Tillman glove that has extra cushioning on the fingers and can rest next to any hot surfaces is advised by Welding Tips & Tricks.

If you want to be able to “sling” your glove off if it gets too hot, that is another feature to think about. It is impossible to swiftly remove gloves with a Velcro strap if they become uncomfortable due to excessive welding heat.

Other crucial aspects include a wool or cotton foam liner for protection and heat-resistant Kevlar thread.

Gloves for MIG Welding

Although some welders utilize high-quality goatskin gloves with a heat-resistant liner for some MIG welding applications, some welders prefer a thicker glove due to the greater temperatures and spatter generated during the MIG process. MIG welding gloves are frequently made from top-grain cowhide, goatskin, or deerskin.

The protection and flexibility that MIG welders require may be found in a top-grain deerskin glove that conforms to your hand.

Gloves For Stick Welding

A thicker leather cut, such as the split grain of elk skin, pigskin, or goatskin, is required for stick welding. You won’t require a highly flexible glove because the stick welding is so straightforward. Since stick welding produces the highest heat and sparks compared to any other type of welding, thickness and protection will be essential.

Welding Gloves Care Tips

Know when to replace your gloves.

Gloves for welding don’t last forever. In accordance with the manufacturer’s guidelines, they must be replaced.

Replace them immediately if they are harmed, cut, have holes, or are abraded to the point that their integrity is jeopardized.

After all, if your welding glove is free of holes, it can shield you from electrical dangers.

Hire reliable contractors.

Include a section in their contract that mentions PPE and when your business anticipates they will be using PPE if you are hiring contract welders.

Conduct line safety inspections in the following steps to assess real performance and ensure they abide by your requirements.

Choose the right glove features.

Because welding is a multi-functional job, welding gloves are a multi-functional piece of PPE. Other than the actual welding, there are several tasks involved in welding. For the chipping hammer and grinder to be used properly, gloves must have a strong, non-slip grip and a flexible reinforced palm.

These gloves can be used for delicate fingerwork and hard, heavy work. You can perform both of these tasks while wearing good gloves. Your gloves should be able to support the true dexterity required to turn the adjustment screw on a small set of vise grips or insert a light welding rod into a stinger.

The welding gloves should be rather firm around the pinky side and the back of the hand, or they should have built-in or sewn-in pads or ridges, as they are also employed as work rests to stabilize and hold the stinger.

Keep in mind that there are persons who are right- and left-handed; therefore, glove supports, and pads must be offered in right or left or created for usage by either hand.

Wrapping Up

To maintain their protective qualities, welding gloves must be cleaned properly. You may get information on cleaning, maintaining, and caring for your gloves from your maker or supplier.

A team effort is required to choose the proper PPE, involving everyone from the welder to the safety expert to the designer and manufacturer. Together, you need to be able to find gloves that are appropriate for the person and appropriate for the task.