Workplace hazards can take many forms, including sharp edges, falling objects, flying sparks, chemicals, noise, and other potentially hazardous circumstances. Employers are required by the Occupational Safety and Health Administration (OSHA) to safeguard their workers from workplace dangers through PPE, such as gloves for hand protection.

The most effective strategy to protect workers is eliminating hazards at their source. OSHA advises using engineering or work practice controls to manage or eliminate hazards to the maximum extent possible, depending on the hazard or working conditions. One example is engineering controls, such as erecting a barrier between a hazard and personnel. Administrative controls, such as job rotation altering, how people carry out their duties.

Employers must provide employees with personal protective equipment (PPE) and oversee its usage where engineering, work practice, and administrative controls are impractical or insufficiently protective. Wearing personal protection equipment helps reduce exposure to several risks. Gloves, foot and eye protection, hearing equipment, such as earplugs and muffs, hard helmets, respirators, and complete body suits are a few examples of PPE.

Components Of Personal Protective Equipment

Details on specific PPE components include goggles, eye protection, face shields, eye protection, gloves, gowns, shoe covers, head covers, masks, and respirators.

Gloves – Gloves can protect you when physically handling potentially infected goods or contaminated surfaces.

Gowns – You can prevent your clothing from being contaminated by potentially contagious substances by wearing a gown.

Shoe and Head Covers – Protect yourself from exposure in a hazardous environment with shoe and head coverings.

Masks and Respirators – Surgical masks help cover your mouth and nose from bodily fluid splashes, and respirators filter the air before breathing.

Face and Eye Protection – Goggles protect only your eyes from splatters. A face shield protects the skin, eyes, nose, and mouth from splashes.

PPE Gloves: Essential Information

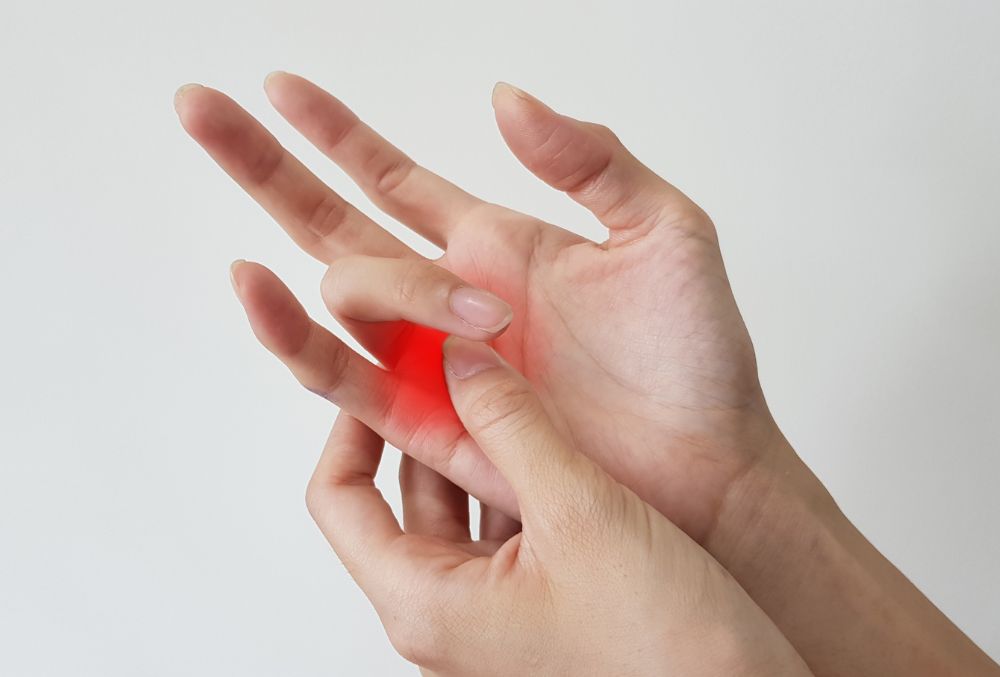

Gloves must be worn when there is a risk of harm or exposure to skin contact with chemicals, infectious agents, heat, cold, abrasive, and cutting items.

Not all gloves are created equal when avoiding skin contact, especially regarding chemical exposures. Gloves eventually let chemicals through, but when the usage circumstances and the glove characteristics—such as thickness, permeation, rate, and time—are understood, they can be used safely for certain lengths.

Types of Hand Protection Gloves

Gloves are not a one-size-fits-all product, like all other safety gear. To ensure worker safety, they must be outfitted with gloves for the tasks at hand and any potential dangers.

The best safety glove selection depends on a variety of things. However, the glove\’s construction material and the level of protection it offers are undoubtedly the most crucial factors.

We will discuss common hand protection gloves to help you identify the safety glove that best suits your needs.

Fabric Gloves

The worker wears these gloves to create a thin, permeable barrier between their skin and the objects they touch. Fabric gloves offer rudimentary defense against hot surfaces, jagged objects, open flames, and puncture dangers. However, keeping hands clean can help avoid minor abrasions and scratches.

For warmth, fabric gloves are occasionally used as liners inside bigger safety gloves.

Coated Fabric Gloves

Compared to fabric gloves, these all-purpose gloves provide better chemical resistance, increased cut and puncture resistance, and defense against the alkalinity of concrete products.

Different materials, including latex, nitrile, polyurethane, and PVC, can create the coatings. A risk assessment can be used to identify the best coating for a particular work.

Despite the widespread use of this glove design, some coatings are known to lose flexibility in cooler work environments. Additionally, they offer less insulation than uncoated gloves do.

Furthermore, while coated fabric gloves do provide some degree of chemical resistance, they should not be used in place of a glove made specifically for handling chemicals.

Latex Gloves and Nitrile Gloves

Latex and nitrile are frequently used in hospitals and laboratories because they offer protection from biohazards, grease chemicals, solvents, and oils.

When the proper size is used, these gloves are form-fitting, enhancing dexterity for handling small objects and doing precise work. However, latex and nitrile don’t offer enough defense against piercings or sharp, abrasive surfaces.

Impact-Resistant Gloves

Even though extended exposure to vibrations can be harmful, they may initially seem harmless. The requirement for worker protection from hand-arm vibration syndrome (HAVS) and its increasing awareness among safety professionals.

Personal protective equipment (PPE) provides some of such protection. Particularly gloves that lessen the exposure of the hand to vibrations and cushion impact.

Vibration-resistant gloves are used in the fabrication industry, where employees may frequently utilize grinders throughout a shift. They are also used in the automotive and construction sectors, where pneumatic instruments like jackhammers may be operated continuously.

Leather Gloves

Good grip, spark resistance, and defense against jagged or abrasive surfaces are all features of leather gloves. Additionally, they shield the wearer from mild heat sources like welding heat or friction heat from a rope sliding across the palms.

When properly cared for, leather gloves are durable, but excessive heat can cause them to harden or fade. When not worn with a liner, they can also cause hands to get dry.

Puncture-Resistant Gloves

These gloves are made specifically to guard against hand punctures. These can be made of braided Kevlar or gloves that look like fish skin. The latter uses a scale- or flake-like structure to prevent penetration from needles, shards, and other puncture dangers.

Aluminized Gloves

Gloves made of aluminum are designed to withstand heat. They are appropriate for use in laboratories with high-heat ovens, furnace and foundry work, and welding activities. They can defend against heat up to 2,000 degrees Fahrenheit because of their insulating and reflecting qualities.

Kevlar Gloves

Kevlar is a heat-resistant para-aramid synthetic fiber that strengthens from a complex chemical structure with many inter-chain linkages. This material has significantly impacted industrial hand protection because it makes it light and strong light and stron gloves andt also remarkably resistant to cuts and abrasions.

Cut-resistant liners made of kevlar are also employed for several additional glove types.

The Bottomline

Safety gloves are a crucial component of the personal protection equipment (PPE) that employees wear to prevent on-the-job injuries. Gloves act as a second skin for employees, enabling them to handle dangerous substances, chemicals, and instruments without sacrificing the necessary dexterity to accomplish their purpose.