Table of Contents

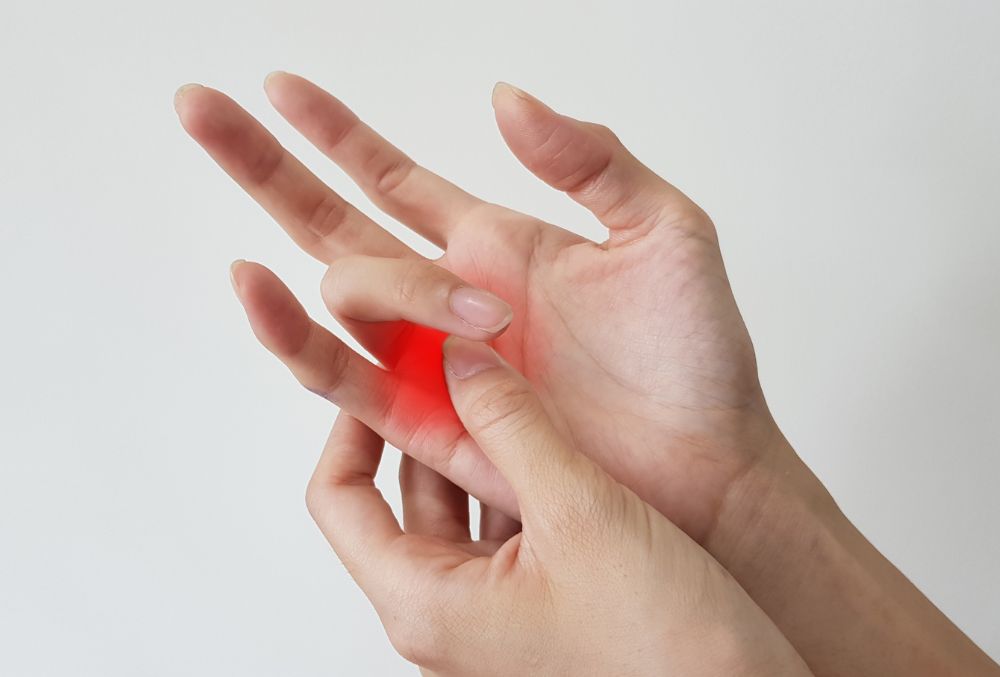

Along with correct process design, using cut- and puncture-resistant gloves can provide people with an additional layer of protection against injuries. Not all gloves offer the same level of security or functionality in every circumstance.

Gloves that can survive cuts from sharp objects are known as “cut-resistant.” Blades, glass, knives, and instruments used in automotive or construction work may fall under this category. They assist in lowering the risk of injury by preventing cuts or abrasions after utilizing tools.

The amount of force or tension a glove can withstand before being torn or punctured by tools or other sharp items is referred to as its puncture resistance. Cut-resistant gloves are not always puncture-resistant, and the opposite is true for the other way around. Gloves that are resistant to punctures may provide defense against needles and other finer tools.

It’s crucial to remember that no glove is 100% cut- and puncture-proof. When a glove is described as resistant, it means that it provides more durability and defense against cuts and punctures.

Cut-Resistant Gloves vs. Puncture-Resistant Gloves

It’s important to protect yourself when working in a setting that contains dangerous materials, sharp objects, and gritty debris. So many workers wear gloves that are cut- and puncture-resistant. These gloves assist in protecting workers from typical occupational injuries such as slashing, crushing, punctures, lacerations, and abrasions.

These gloves are frequently confused for being the same. Both, however, have unique qualities of their own and provide varying degrees of protection. What distinguishes cut-resistant gloves from puncture-resistant gloves, then? Let’s see and learn.

Cut-Resistant Gloves

Work gloves’ outer layer is prevented from being broken by cut-resistant gloves. They can survive cuts from blades, glass, tools, and knives used in the automotive or construction industries. They dramatically lower the risk of industrial injuries by lowering the likelihood of cuts and abrasions after utilizing tools. Work gloves that can withstand cuts are also a great defense against flying objects.

Cut-Resistant Gloves Buying Guide

Choosing the right cut-resistant gloves is essential when working with machinery or instruments that are sharp and could cause hand injury. When investigating cut-resistant gloves, keep the following important characteristics in mind to provide maximum protection.

Resistance Level

It is essential to select gloves that are certified in accordance with cut resistance standards if you want effective hand protection. Examples of these include ANSI/ISEA 105-2016 and EN 388. These certificates confirm that the gloves adhere to national industry safety regulations as well as indicate the degree of protection that they can offer. You can be completely confident in the effectiveness of approved gloves. Additionally, it implies that you may rely on them to meet the standards needed for efficient cut resistance.

Durability

Verify the gloves’ sturdy, cut-resistant materials and solid stitching. These elements will guarantee the product’s durability and efficacy in safeguarding your hands from potential hazards. Try to find fibers with great performance, such as Dyneema or Kevlar. These textiles were created specifically to maintain cut resistance.

Comfort

When wearing cut-resistant gloves, it’s crucial to make sure they fit properly for maximum dexterity and comfort. Make sure your fingers can move freely without feeling constrained by the gloves.

Coating Materials

When working with sharp things, choosing gloves with additional coating materials like nitrile, foam, vinyl, or polyurethane can offer additional protection against cuts and enhanced grip. These materials also allow for flexibility. It may be advantageous to select glove materials that are resistant to punctures, oil spills, or hot liquids as an additional layer of protection, depending on your line of work.

Grip

Choose gloves that have a solid grip surface in mind. They will remain stable in greasy or damp conditions thanks to this. Therefore, when handling tools and other potentially hazardous objects, they won’t slip or slide. Silicone coatings are excellent for enhancing grip while preserving hand dexterity and flexibility.

Puncture-Resistant Gloves

Puncture-resistant gloves provide defense against pressure or force before a sharp object or instrument may pierce them. Although they may sound like cut-resistant gloves, they are designed to resist needles, tattoo guns, and other fine-pointed objects rather than sharp objects. Gloves that can withstand punctures may not provide total protection, but they can lower the risk of injury. If you’re in a circumstance where you have gloves made of Kevlar, place another layer on top of them to provide further protection.

Puncture-Resistant Gloves Buying Guide

We are aware of the significance of obtaining gloves that will shield construction, utility, and industrial employees’ hands from workplace hazards like cuts and punctures. We appreciate what you do, which is why we’ve gathered a few crucial items to think about:

Materials

The type of material the gloves are made of affects how resistant they are to punctures. To find puncture-resistant gloves, look for materials like kevlar, leather, or nylon.

Some puncture-resistant gloves may be certified to fulfill particular standards, such as those established by the European Committee for Standardization (CEN) or the American Society for Testing and Materials (ASTM). It may be crucial to select gloves that have been approved to fulfill specific criteria if you work in a regulated business.

Durability

Select gloves that are durable and up to the challenges of your work or activity. Look for gloves with reinforced fingertips or other durable features that are constructed of high-quality materials.

Fit

To ensure that the gloves offer the protection they are designed to, proper fit is crucial. Make sure the gloves are the proper size and are neither too tight nor too loose.

Comfort

When choosing gloves, keep in mind that depending on your work or activity, you may need to wear them for prolonged periods. Prioritize comfort over style, but if you can have both style and comfort, then that will be great.