Compliance with hand protection regulations and standards is crucial in every workspace. Not all safety gloves offer equivalent protection. Even though they may look comparable, gloves made for one type of hazard may not offer enough protection against another. How can you ascertain which gloves provide proper protection?

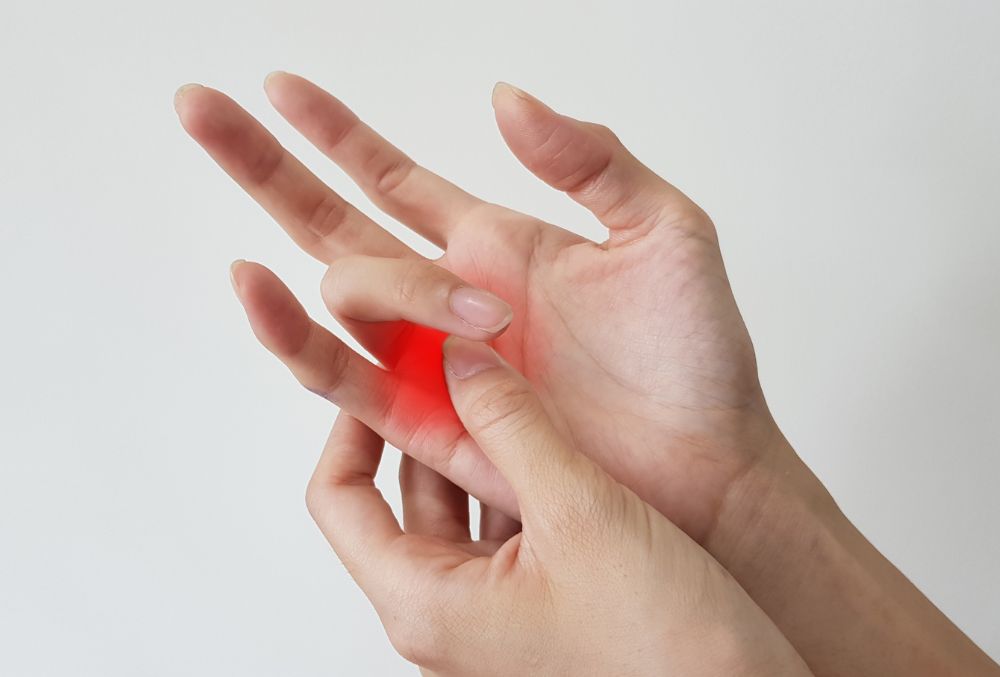

Direct contact with chemical and biological threats, thermal or chemical burns, electric shock, bruising, abrasions, cuts, punctures, fractures, or amputations are all possible hands and arms risks. Arm covers, finger guards, and gloves are examples of protective equipment.

The performance characteristics of the glove in connection to the tasks to be done and the risks present in the workspace must be your basis for selection.

Conducting a risk assessment is one efficient way to identify known threats and develop preventive or protective plans to handle them. This procedure enables you and your staff to jointly identify all known risks connected to a task or assignment before developing safeguards and resources for hand protection products to keep workers safe while carrying out their responsibilities.

Hand Protection Regulations and Standards

You cannot operate easily without compliance with hand protection regulations and standards. Here are some fundamental aspects you must consider.

Standards for Protective Gloves

Outlines the main specifications for most protective gloves, including information on glove sizing, ergonomy, dexterity, innocuousness, product marking and packaging information, and electrostatic qualities. The table below shows glove sizing based on hand length and circumference:

| SIZE | HAND CIRCUMFERENCE (MM) | HAND LENGTH (MM) | GLOVE LENGTH (MM) |

| 6 | 152 | 160 | 220 |

| 7 | 178 | 171 | 230 |

| 8 | 203 | 182 | 240 |

| 9 | 229 | 192 | 250 |

| 10 | 254 | 204 | 260 |

| 11 | 279 | 215 | 270 |

Abrasion Resistance

Circular glove specimens are rubbed against the designated grit paper in a Lissajous pattern while subjected to a force of 9 kilopascals to test the resistance to abrasion. The specimen is observed after a certain number of rubs based on the performance level to assess the degree of abrasion. Once the sample has completely broken through, failure is seen. High-performance materials can be evaluated for more than 8,000 cycles before the sample starts to degrade.

Cut Protection

The Circular Blade Cut Resistance Tester uses the Coup Method to determine a material’s cut resistance. An examination sample is taken from a glove and clamped in a holder attached to the apparatus. The sample is softly touched by a circular blade that has been lowered. The machine stops when the blade enters the sample while rotating and traveling back and forth across the fabric. The cut index is calculated based on how many times the revolving blade has cycled.

The TDM blade test involves moving a tomodynamometer with a straight blade across the sample glove in a single motion, using a different blade each time. To anticipate the force necessary to cut through the glove in 20mm of travel, graphs are plotted based on the “stroke length” before cut-through for various forces. A score from A to F, with F being the highest grade, is determined by this force.

Tear Protection

Tests requiring extension, stretch, and compression against distance are performed using the tensile tester. The force required to rip a fabric determines its tear resistance. For tearing force, four samples are analyzed. Two rectangular specimens are taken across the palm of two different gloves, and two specimens are taken along the length of two gloves, both with a 50mm longitudinal slit. Each specimen’s peak tearing force is noted, and the lowest of the four findings obtained is used to provide a classification level of 1-4.

Puncture Protection

Tests requiring extension, stretch, and compression against distance are performed using the tensile tester. The amount of power needed for a needle to pierce a fabric is known as its puncture resistance. At a rate of 100mm/min, a 4mm probe with a rounded stylus is pressed 50mm deep into the material. The test is conducted on four specimens, where the maximum force value is noted. The puncture score, assigned between levels 1-4, is determined by the result, which is the lowest value received.

Convective Heat Resistance

This test exposes gloves to a flame heat source while never touching the flame. The glove’s many surfaces are put to the test.

The back of the hand and samples of the palm are heated in a controlled environment as part of this examination. The duration necessary to elevate the glove’s interior temperature by 24°C will be determined.

Radiant Heat Resistance

This test returns the gloves to the test to see if the various materials can withstand intense heat radiating through them. The tests involve exposing glove samples to a radiant heat source, and they have the same objective as the Convective Heat Resistance test: to determine how long it takes for the inside temperatures to rise by 24°C.

Molten Metal Resistance

This test is intended to determine how well hands are protected when handling small amounts of molten metal. A good example of where this glove would be utilized frequently is welding.

Two samples from the palm and two from the back of the hand are subjected to tiny drops of molten metal, such as copper, in a controlled environment during the test. Protective performance is calculated based on how many drops are required to raise the temperature by 40°C on the sample’s opposite side. It is also tested if the cuff is made of a material other than the palm or back of the hand.

Final Thoughts: Importance of Compliance

Compliance with hand protection regulations and standards is vital to business owners and workers. The gloves you choose should suit the dangers and hazards experienced. You should consider the task, the user’s size and comfort, the type and duration of contact, and the protection you want to apply. It will then give you the knowledge and information you need to be precise about the glove you should use to protect yourself from risks.

Although many management systems will include a PPE risk assessment, we advise that the specifics of your activity-specific risk assessment identify any PPE and the standard that must be followed to safeguard the wearer.

Remember that you must choose the PPE that offers the optimum hand protection against the risks listed in your risk assessment. The improper gloves can increase risks while giving your staff a misleading sense of protection, whether inadequate or overrated for the hazard.