If you work in the construction industry, you must wear the proper protective gloves if a workplace hazard assessment finds that you could suffer potential occupational hand injuries that cannot be prevented by engineering and work practice controls. A few potential workplace hazards are electrical risks, chemical or thermal burns, skin absorption of dangerous chemicals, bruising, abrasions, cuts, punctures, fractures, and amputations. Protective hand gloves, finger guards, arm coverings, and elbow-length gloves fall on the list of protective gear.

Construction workers should know all feasible engineering and work practice controls to eliminate risks and use PPE to offer extra safety against construction work risks that other means cannot avoid.

Hand Protection for Construction Workers

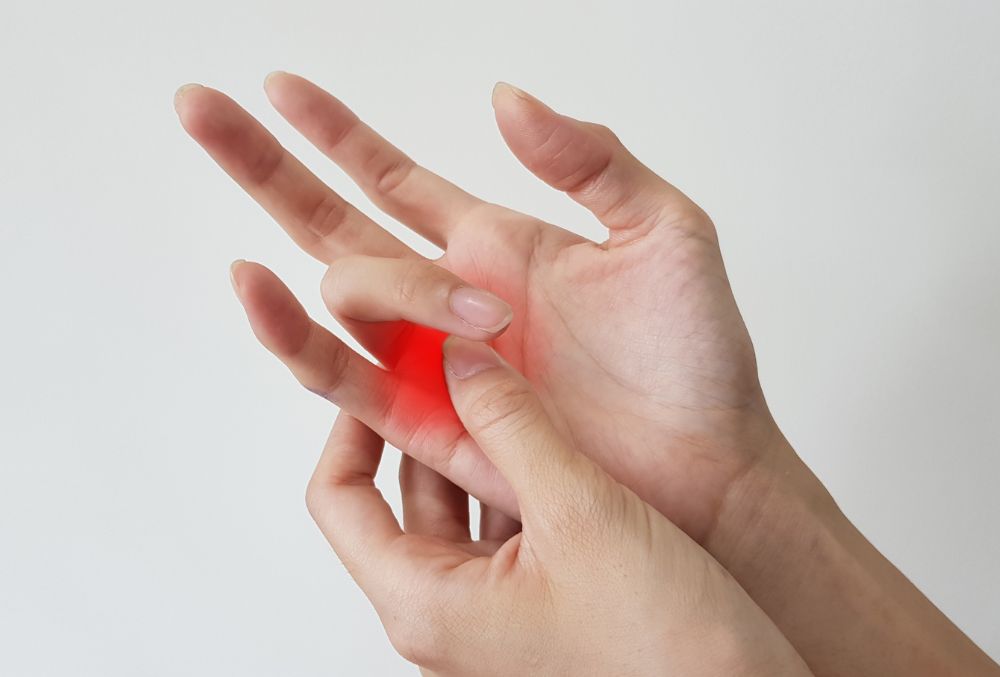

The Bureau of Labor Statistics found 102,350 lost time cases due to hand injuries. One million workers are treated in an ER for hand injuries annually, and seventy percent of workers who experienced a hand injury were not wearing protective hand gloves.

Today’s protective gloves come in several styles to guard against various hazards. The kind of glove to choose will depend on the construction operation and the type of hazard.

Choosing the proper pair of protective gloves is difficult due to the range of possible occupational hand injuries. Construction workers must wear gloves that are particularly made for the risks and duties they face since gloves made for one purpose may not offer adequate protection for another, even though they may appear to be a suitable safety measure.

Types of Protective Gloves

- Leather Gloves

- Latex or Insulating Rubber Gloves

- Polyurethane Gloves

- Nitrile Gloves

- Chemical Gloves

We will discuss more about protective gloves in the safety tips below.

5 Safety Tips for Construction Workers

A construction site is a hazardous environment for your hands. Cuts, bruises, abrasions, punctures, and other hand injuries are possible without the proper safety gear. However, finding the appropriate pair of safety gloves can be difficult because of the need to think about agility and comfort. Here are some suggestions for keeping your hands safe when building. Proceed reading.

Identify Site Risks and Hazards

Assessing the hazards that could affect your hands is the first step in hand protection. You can then use this information to select the appropriate protective glove for the issue.

Here are some examples of potential dangers to keep in mind:

- Contact injuries from sharp things, such as tools or equipment, can cause cuts and punctures.

- Broken bones from falling objects or accidental tool impacts during surgery Surgical burns from chemicals, hot implements, or fire

- Chemical sensitivities and product allergies

- Repetitive motions of using tools can cause muscle and bone damage.

- An accident caused by carelessness

Protective Equipment Includes Gloves

You can now choose the appropriate hand-protective equipment after identifying the risks and hazards at your building site. To help you get started, here are some glove materials:

Leather Gloves

One of the most adaptable pieces of hand protective equipment is leather gloves. It can protect you from risks like cuts and abrasions. One example is the safety gloves constructed of cowhide leather grain hide for the building, farming, and logistics sectors. But in addition to offering hand protection, it significantly improves the wearer’s dexterity.

Polyurethane Gloves

Tools are more prone to slip out of hands and hurt people when wet. Polyurethane is applied to the palms and fingertips, which increases grip while using greasy and wet equipment. In addition to that, it can also withstand puncture, ripping, and abrasion.

Nitrile Coated Gloves

The oil resistance of nitrile is well known. It is, therefore, frequently utilized in construction gloves. The back of the gloves is reinforced with flexible thermoplastic to defend against impact and pricks. The Velcro clasp on the cuff makes it comfy to wear as well.

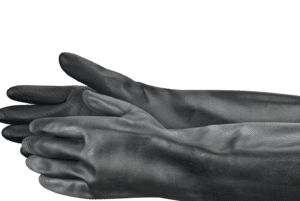

Insulating Rubber Gloves

Natural (latex) rubber gloves are quite versatile due to their comfort. Their tensile strength, flexibility, and temperature resistance are all top-notch. These gloves are resistant to abrasions from grinding and polishing, and most acids, alkalis, salts, and ketones are found in aqueous solutions.

Chemical Gloves

Different types of rubber, including natural, butyl, neoprene, nitrile, and fluorocarbon (viton), or different types of plastic, including polyvinyl chloride (PVC), polyvinyl alcohol, and polyethylene, are used to make chemical-resistant gloves. For enhanced efficiency, these materials can be mixed or laminated. Generally speaking, the better the chemical resistance, the thicker the glove material, yet thick gloves may reduce grip and dexterity, compromising safety.

Wear Protective Gloves Properly

The fit is important in addition to the safety gloves’ material. If not, there is still a chance that the wearer will get hurt. Accidents could occur, for instance, if a worker continually fiddles with their gloves rather than concentrating on the task at hand. Additionally, the additional material may snag on apparatus and instruments.

Tools may slip out of the hands if gloves are too loose or tight, limiting the wearer’s range of motion. Finally, cramping and blistering can also be brought on by ill-fitting gloves.

Ensure the safety gloves are snug on the hands but not too tight that they could be problematic while worn.

Maintain Protective Gloves

Before each usage, protective gloves should be checked to make sure they are not ripped, punctured, or rendered ineffective in any other manner. A visual inspection will help find rips or tears, but a more comprehensive examination that involves putting water inside the gloves and tightly rolling the cuff toward the fingers can aid in finding any pinhole leaks. Discolored or stiff gloves may also indicate flaws brought on by excessive use or deterioration from chemical exposure.

Any less protectively effective gloves should be properly disposed of and replaced. The absorbent properties of chemical-resistant gloves should be carefully considered when reusing them. The decision to reuse gloves exposed to chemicals should consider the chemicals’ toxicity and variables, including exposure time, storage conditions, and temperature.

Wrapping Up

Construction workers are subject to risks when handling equipment and power tools on the work site. If left unattended, this can result in wounds, burns, bruises, and injuries that may need medical attention. However, you can avoid workplace hand injuries by wearing the appropriate protective gloves and practicing excellent work habits.