Modern living is impossible without electricity, used in every facet of our daily lives. However, it can be very dangerous if necessary safety precautions are not taken. Electrical dangers can result in fatalities, severe burns, and other catastrophic injuries. In this post, we will talk about electrical safety, risks, their causes, and the preventative steps that may be performed to maintain electrical safety.

Electrical Hazards

The Occupational Safety and Health Administration (OSHA) defines an electrical hazard as a major occupational risk that puts employees in danger of being burned, electrocuted, shocked by fire or explosions, or electrocuted by arc flash or arc blast. We can take precautions to safeguard ourselves by recognizing these risks and comprehending how they occur.

Electrical Shock

The most frequent electrical hazard is electrical shock, which can happen when someone comes into contact with an energized surface or object or directly with live electrical conductors. The shock’s intensity can change depending on the current flow and exposure time. Electrical shock can result from burns, muscle spasms, and cardiac collapse.

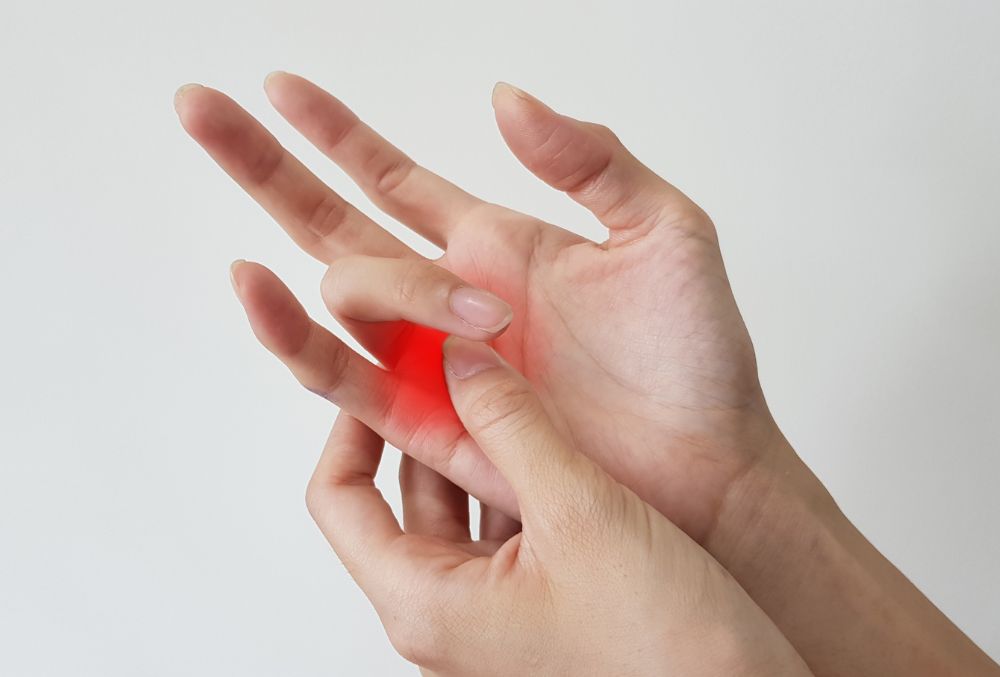

Electrical Burns

Electrical burns can happen when a person comes into touch with an electrical conductor, or a flashover or arc produces extreme heat. Electrical burns are brought on by electrical energy traveling through the body. Electrical burns can be painful and seriously harm the skin and surrounding tissues.

Electrical Fires

Electrical fires can start when an electrical wire or equipment overheats and sets nearby items on fire. Overloaded circuits, broken wiring, or defective electrical equipment can all result in electrical fires. Electrical fires may spread quickly and are often challenging to put out.

Electrical Safety Tips

Numerous safety tips can be used to ensure electrical safety. Some of the best electrical safety control measures are listed below:

Let Only Experts Do The Job

Ensuring that only knowledgeable and experienced people are permitted to undertake electrical tasks is the most crucial part of electrical safety. Precise knowledge, abilities, and experience are needed to execute electrical work safely. A skilled worker is one who has obtained the training, knowledge, and experience required to perform the task safely and effectively. Additionally, this person must be knowledgeable about electrical risks and how to avoid them.

Making sure that employees are knowledgeable and trained is the employer’s duty. Programs for training and certification can be utilized to ensure that employees have the skills and knowledge needed to complete electrical work safely. Before authorizing an individual to operate on electrical equipment, an employer might also check their training, education, and experience.

Do Not Work On Live Equipment

Working with live electrical equipment is very risky and can lead to electric shock, harm, or even death. Therefore, adhering to the isolation and multi-lock system is essential to prevent injury from equipment that has unintentionally been turned on while serviced by several crafts.

The isolation and multi-lock system entails cutting off the power to the equipment, locking the disconnect in the off position, and tagging the apparatus to show that work is being done. This method ensures that when maintenance or repair work is done, the equipment cannot accidentally be powered on.

A multi-lock system is designed to prevent equipment from accidentally turning on while serviced by separate vessels, preventing injuries. The requirement is determined jointly by the executing authority and the issuing authority, and the issuing authority grants the work permit to an electrical professional qualified to separate the electrical equipment from the substation. The multi-lock pad’s locks are installed by the executing authorities and the qualified electrical person in accordance with color coding.

Every lock must have a unique number, and the key must have the same number. The person who installed the lock is in charge of keeping the key after it has been locked. After obtaining all essential licenses, electrical maintenance will have to remove the lock last, and the lock should be removed by individual craft as their duty is done.

Use Personal Protective Equipment

When handling electrical equipment, personal protective equipment (PPE) is essential. Insulated gloves, safety glasses, and hard hats are standard PPE for electrical work. The best PPE will depend on the exact job and the dangers involved. PPE can shield employees from electrical risks and stop accidents.

Regular Inspection and Maintenance

Electrical equipment should be regularly inspected and maintained to help spot potential risks and avert accidents. To do this, look for wear and tear indicators like frayed wires, loose connections, and cracked insulation. It’s crucial to quickly repair or replace broken equipment to avoid mishaps.

Perform Safety Trainings

Electrical safety training is crucial for electrically-trained and non-electrically-trained employees operating near electrical equipment. The possible risks connected to electrical equipment, the significance of avoiding electrical equipment, adhering to safety protocols, and the appropriate use of PPE should all be covered in training for these personnel.

Have An Electrical Safety Checklist

Checklists for electrical safety can be used to identify potential risks and confirm that safety procedures are being followed. These checklists can inspect electrical equipment, examine wiring and grounding, confirm lockout/tagout protocols, and guarantee that personal protective equipment (PPE) is utilized correctly.

Create An Emergency Response Plan

If there is an electrical mishap, there should be a plan for responding to it. The response to electric shock, electrical fires, and other electrical emergencies should be covered in this strategy. The emergency response strategy should be taught to employees with access to the right first aid supplies.

Prioritize Electrical Safety

Modern life is impossible without electricity, but if safety precautions are not taken seriously, electricity can also be harmful. Electrical dangers, including faulty wiring and equipment, weak connections, inadequate grounding, overloading of equipment, and more, can result in electrical shock, burns, and fires.

Electrical work should only be performed by qualified and experienced people who have received the necessary training and certification, and safety measures like isolation and multi-lock systems should be implemented. When safety precautions are taken properly, electrical risks can be avoided, and lives can be saved. Failure to take safety precautions can have catastrophic repercussions.